Boat Repairs

Few things are more disheartening toward boatowner than observing the fuzzy edge of broken fiberglass. But the repairability of fiberglass is regarded as its most readily useful faculties. The absolute most horrifying hole in a fiberglass hull is quickly healed with a little bit of cup fabric, a supply of resin, and equal parts ability and treatment. And also the restoration is less patch than graft-a brand-new bit of epidermis indistinguishable from old.

Fiberglass lay-up is simply levels of cup textile saturated with polyester (or epoxy) resin, yet many boatowners imagine a self-applied repair as just a little more durable than a damp Band-Aid. This might be a false concern. Follow some easy principles and your lay-up will be equally durable while the other countries in the watercraft.

Cut-away the Damage

Effect damage often leads to some associated delamination. Touch the effect location aided by the end of a synthetic screwdriver handle to look for the extent of damage; solid laminate noises sharp, delamination dull. Check in the boat to ensure nothing is in the manner, then make a circular or oval cut to remove the damaged area. Never ever attempt to save your self damaged fiberglass; always slashed it out and change it with new laminate. Examine most of the sides and expand the hole if you find any additional delamination.

Operating from Inside

In the event that damage location is little and above the waterline, make the repair from the hull, if at all possible. You will bevel the edge of the opening with a 12-to-1 chamfer, so if you repair a 3-inch diameter hole through a 1/2-inch-thick hull through the exterior, you end up with about 15 ins (diameter) of area injury to refinish. Repair it from inside and you have only a 3-inch hole to refinish.

Another reason to make the restoration from inside is that you can right back the hole externally with a polished surface, producing a mold enabling you to lay-up the fix the same way the motorboat had been built-gelcoat first. Very little finish work may be required.

Dewax

Before grinding, constantly clean the region round the gap carefully with a dewaxing solvent. The original fiberglass need traces of mold launch on exterior surface and wax surfactant regarding internal surface. If you fail to remove the wax first, grinding will drag it into the bottom of the scratches and weaken the bond.

Grind

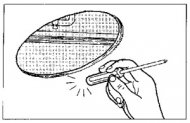

During lay-up procedure, because each layer is used before the past one fully remedies, each application of resin backlinks chemically aided by the earlier one to develop a solid structure-as though most of the layers were over loaded simultaneously. Unfortunately, no matter what powerful the laminate-to-laminate bond, the original bond of any restoration is mechanical, not substance. Consequently, milling is key to getting a good fix.

Make use of a disk sander full of a 36-grit disk to grind a 12-to-1 bevel around the perimeter associated with hole around. Additionally grind a rectangular area of the inner surface some inches beyond the bevel to support a finishing layer of fabric. Shield your eyes with goggles plus lungs with a good dirt mask. Extended sleeves wil dramatically reduce epidermis discomfort. Tilt the sander in order that only one region of the disk is touching the area in addition to dirt is discarded from you. Once you clean away the dirt and wipe the region with an acetone-dampened rag, the sanded area need a uniform lifeless look.

Mask and Mold

To stop any resin operates from adhering, supply the exterior surface of the skin round the hole a heavy coating of paste wax, using care to not get any from the edge or inside the gap. Mask the location underneath the hole.

Cut a scrap of smooth synthetic laminate (Formica) or slim clear acrylic (Plexiglas) a base bigger than the opening. Wax this backer, then spritz it with polyvinyl alcohol (PVA) mold release. Screw or tape the backer to the external surface. If hull is level or curving in mere one way in the damage area, the backer will believe the correct curve. If the hull is spherical, in other words. curving in 2 instructions, acrylic screwed into the hull can be coaxed to the correct shape if warmed with a heat weapon (before applying the mold launch).

Textile

Cut sufficient fiberglass fabric to match the opening. Until you have actually reason to check out a different sort of routine, start out with two levels of 1 1/2-ounce pad, then alternate mat and 6-ounce fabric. The sheer number of laminates may be decided by the thickness associated with the hull; you will approximately need one level for each and every 1/32 inches. Slice the first layer of pad the full measurements of the floor depression, then slashed subsequent pieces about an inch smaller. This order of largest piece very first, then progressively smaller pieces is the method that you will apply this new material. We do so this counterintuitive way, particularly with polyester resin, since it maximizes the location associated with secondary relationship, the adhesion regarding the brand-new cloth towards the old laminate.

Utilizing Polyester or Vinylester Resin

For above-the-waterline fixes you can make use of either polyester or vinylester resin. Of course, for a much stronger restoration you can even utilize epoxy, yet not in the event that surface of fix will be gelcoat. (you should utilize epoxy for underwater repairs.)

If you're doing all your fix with polyester or vinylester resin, you may need laminating resin. Laminating resin cannot completely cure while exposed to environment, makes it possible for you to get a chemical relationship amongst the multiple laminates you will end up applying. To get the last laminate to cure, you merely seal it from atmosphere, either with a plastic or by covering it with polyvinyl alcoholic beverages (PVA) mildew release.

Catalyst

The catalyst for both polyester and vinylester resin is methyl ethyl ketone peroxide, or MEKP. Do not confuse MEKP using common solvent MEK; they may not be exactly the same.

Polyester resin generally needs one to two % of hardener by volume (stick to the manufacturer's guidelines). Generally of thumb, four drops of hardener will catalyze 1 ounce of resin at 1 percent. Be sure to blend the catalyst in completely or part of the resin will likely to be undercured, weakening the lay-up.

You are able to adjust the remedy time by the addition of more or less catalyst. Temperature, climate, plus the depth for the laminate all affect curing times. Some experimentation is generally required. The mix shouldn't kick (start to harden) in under half an hour. Hardening in about couple of hours might be perfect, but immediately is equally as good unless the delay will hold you up. Always err privately of not enough catalyst; in the event that you add an excessive amount of, the resin will "cook, " resulting in a weak lamination.

Gelcoat

Gelcoat is essentially pigmented polyester resin. Start the repair by spraying or brushing about 20 mils of color-matched gelcoat onto the waxed backer. Check out the gelcoat depth with a toothpick; 1/32 is about 30 mils.

Lay-up

When the gelcoat kicks, damp it with polyester resin and lay-up the first two levels of pad and something level of cloth, compressing all of them resistant to the gelcoat and dealing on all voids and bubbles with a resin roller and/or a squeegee.

Allow very first three plies kick, after that lay-up four additional plies. Never lay up above four plies at a time and/or generated temperature may "cook" the resin and deteriorate it. Carry on the lay-up four plies at the same time until the restoration is flush with all the interior area.

Complete

For a finished appearance, cut a rectangular bit of pad and one somewhat larger of cloth and apply these within the area, smoothing these with a squeegee. Seal this top layer with synthetic or PVA to allow a complete remedy.

Take away the backer through the exterior area. Fill imperfections when you look at the brand-new gelcoat with gelcoat paste and invite it to heal completely. Cleanse the location all over plot, then sand-if necessary-and polish the repair area.

You might also like

|

Don Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, Sailbo Book (International Marine/Ragged Mountain Press) |