Awlgrip Topcoat

Facts & Fiction Regarding Repairing & Buffing Topcoats

Fender wipe, difficult moorings and basic wear & tear all signify topcoat fix and upkeep in-service is an undeniable fact of life. Just what exactly you may not need to find out?

Captains and crew tend to be progressively getting involved in the choice of paint, and 'repairability' is progressively sought-after, but you can find pitfalls which you are able to and really should avoid.

Topcoats provided for yachts could be just split into two types based on their fundamental resin biochemistry:

So what may be the difference between the AwlGrip and AwlCraft resins?

Well, it seems that dimensions does matter- molecular size.Polyester Urethane particles are a lot smaller compared to Acrylic molecules. Then when they treat the Polyester urethane kinds a stronger matrix which gives a more difficult, more abrasion resistant movie, with better chemical opposition compared to Acrylic.

Acrylics however, do have crucial advantages of their. These are generally much more flexible in application, trap less dirt and tend to be for that reason buffable (but more about that later on). So are there good reasons to select each. Both Awlgrip and Awlcraft 2000 will resist staining and provide long lasting gloss.

How they work

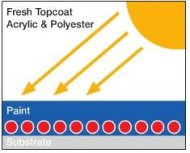

A primary reason these shows be as durable while they do is mainly because they stratify directly into a resin wealthy layer in the surface and a pigment rich level underneath. The exterior layer provides longterm defense for the pigment particles, which improves color and gloss retention and offers the deep gloss associated with high-quality urethanes. Any buffing will remove film width, which often may lower longevity and can even affect makers' guarantee.

Buffing your topcoat be it element of a restoration, touch-up, polishing or maintenance routine

So what the results are when you buff the paint? This will depend regarding resin kind, acrylic or polyester. While it is true that EACH topcoat can be buffed, don't assume all topcoat should be unaffected by the procedure.

So what the results are when you buff the paint? This will depend regarding resin kind, acrylic or polyester. While it is true that EACH topcoat can be buffed, don't assume all topcoat should be unaffected by the procedure.

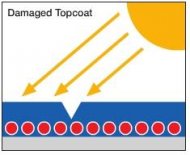

The diagrams below tv show just how biochemistry and buffing impact the overall performance of this coating.

Undamaged, the resin rich outer layer provides defense against weathering.

Here we come across a simulated damaged area that needs buffing away. This may be something such as a scratch as an example.

This diagram shows what goes on once you buff a polyester urethane. Considering that the paint is a tremendously difficult rigid film to eliminate the scrape you need to reduce profoundly in to the paint, ultimately causing publicity for the pigments. This seems shiny to begin with although long-lasting overall performance for the finish is affected. Regular applications associated with the Awlcare defensive Polymer Sealer would be required to keep up with the finish.

Very light polishing of a Polyester Urethane might not result in this issue but this is certainly rarely adequate to remove scratches and most certainly not adequate to merge places that have been handled with color.

Whenever an acrylic urethane is buffed, as a result of reduced cross-link thickness the melting point of this resin is much lower in other words. it really is gentler. Whenever buffing is performed the resin-rich layer "melt" and reflow to the scrape. You are able to retain an in-tact resin-rich layer at the area protecting the pigments and not losing significant thickness. The sides of touch ups could be blended very carefully in the same way. Future overall performance is not impacted just as much for the resin level continues to be. Use of Awlcare will protect this resin level and further increase the life associated with finish.

Listed here are some easy tips from buffing systems producers:

Listed here are some easy tips from buffing systems producers:

- Cleanse the top with Awlwash prior to starting

- Let the surface to dry

- Apply an excellent level of polishing chemical evenly

- Make use of a clean buffing pad

- Position the pad on the surface before you begin

- Buff relating to producer's treatments

- Begin at a sluggish buffing speed

- Cut overly to the paint level

- Push down hard from the buffing device

- Make use of extortionate speed because of the buffing pad

- Buff in direct sunlight or if perhaps the outer lining is hot

- Enable the element to dried out on top

Rise above the Factory-Looking Shine

Therefore, you have selected your Awlgrip finish, how will you protect it and ensure that it it is searching perfect day after day?

Awlgrip only advises Awlwash and Awlcare for cleansing and safeguarding your finish

Awlgrip seems that the usage of Awlwash and Awlcare will expand the life associated with the topcoat with regards to gloss and color retention.

Awlwash Wash Down Concentrate- 73234

A highly effective detergent for cleaning, but still gentle enough for regular usage on Awlgrip and Awlcraft 2000.

Awlwash has-been extensively tested in Awlgrip's laboratories and in the harsh yacht environment.

- Awlwash doesn't consist of alkalies, acids or abrasives and is no-cost rinsing, which reduces drying out time

- Awlwash is biodegradable and will come in a refillable quart, "Idea 'N' Measure" container, which makes it an easy task to obtain the correct mix ratio: One ounce of Awlwash per gallon of fresh water

Awlcare Defensive Polymer Sealer- 73240

Awlcare may help temporarily seal and restore shine to decorated areas which have become permeable due to age or mistreatment. As soon as a painted area becomes permeable it allows dirt to collect at first glance making the normal washing procedure more challenging. Regular applications of Awlcare enable seal the porosity, helping to maintain an effective appearance until there was time to repaint.