Interlux Paint Guide

Painting bare fiberglass boats

Painting bare fiberglass boats

1. Since the boat may do not have been painted, just take additional treatment and time in organizing the bottom before continuing into the system of preference. Clean area very carefully, begin by the removal of all contaminants and "shape launch Wax" on top the following.

2. Scrub the surface thoroughly using water and soap and a rigid brush. Flush with fresh-water to eliminate detergent residue. Allow surface to dried out. After that proceed with either of this two following options:

Choice 1: employ with a maroon, 3M, Scotch-Brite pad and scrub really. Flush with fresh-water or wipe off with a clean, wet fabric making sure no traces of Fiberglass exterior Prep remain.

Choice 2: Dampen cheesecloth with Interlux Fiberglass Solvent Wash 202. Rub carefully to eliminate all area contamination and cleansers. Wipe-off with a clear, dry rag before fluid dries. Wipe only a few feet at the same time.

3. Softly spray the outer lining with water to insure all contamination is removed. If water beads up or separates, wax continues to be current. Perform until liquid no longer beads. At this point all mold launch representatives, wax and other pollutants must have already been eliminated. Proceed to among the after No Sand Method, Interprotect Method or Sanding Process.

BARE FIBERGLASS - SANDING SYSTEM After the area is prepared as described above Sand entire area really with 80-grit sandpaper until level matte finish is gotten. Make every effort to transform sandpaper regularly. Wipe off sanding residue with Fiberglass Solvent clean 202. Apply two coats the least Interlux antifouling paint.

After the area is prepared as described above Sand entire area really with 80-grit sandpaper until level matte finish is gotten. Make every effort to transform sandpaper regularly. Wipe off sanding residue with Fiberglass Solvent clean 202. Apply two coats the least Interlux antifouling paint.

Whether or not the ship is brand-new or a few years old "Mold launch Wax" and other pollutants like soil, grime, dirt, essential oils as well as roadway sodium can be present regarding bottom associated with boat. You should correctly prepare the base of the ship before proceeding.

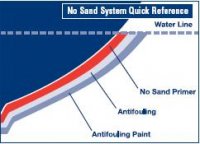

PROGRAM 1: NO SAND PROCESSBottom painting bare fiberglass, Polyester or Vinylester gelcoats or epoxy resin

- Stick to the Boat Hull planning instructions above.

- Only 1 layer of Fiberglass No Sand Primer is required. Antifouling overcoat times vary as a result of broad variations in heat and moisture. The only real safe solution to determine as soon as the Interlux Fiberglass No Sand Primer is "Ready-to-Overcoat" is always to look at the paint movie using the "Thumb Print" test. In the event that primer feels tacky and you will leave a thumb printing in paint movie without getting any paint on your own flash, the Fiberglass No Sand Primer is "Ready-to-Overcoat". Testing the paint movie in the area you began applying the primer no later on than half an hour after starting the application form. Manage testing every fifteen minutes with the "Thumb Print" test until achieving the "Ready-to- Overcoat" stage. Immediately, begin to use the Interlux antifouling paint once the primer has now reached the "Ready-to-Overcoat" phase.

Top Tip

- One coating Fiberglass No Sand Primer applied within advised WFT; may well not conceal the gelcoat completely when applied precisely.

- Fiberglass No Sand Primer is not used in combination with here Interlux antifouling shows: VC17m® Extra, VC17m,